Can Servos Be Used Like Brushless Motors?

In the world of motion control systems, both servos and brushless motors play vital roles. Understanding their capabilities, similarities, and potential applications can be critical in choosing the right component for a specific use. A question that often comes up in engineering circles is: Can servos be used like brushless motors? This guide explores the characteristics of servos and brushless motors, their potential interchangeability, and how you can optimize their use to meet your needs.

Key Components of a Servo Motor

- Motor: Typically a DC or AC motor that provides the power for the servo.

- Gearbox: Often used to reduce speed and increase torque.

- Control Circuit: Processes signals and provides appropriate power to the motor.

- Feedback Sensor: Provides real-time data to the controller for accurate positioning.

Applications of Servo Motors

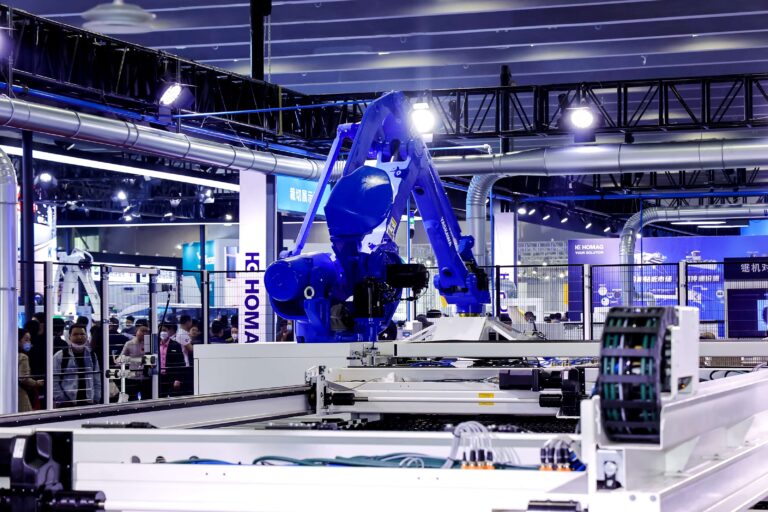

Servo motors are widely used in robotics, CNC machines, conveyor systems, and industrial automation where precise control is necessary. They excel in situations requiring accurate speed and position control.

Advantages of Servo Motors

- High Precision: The feedback loop ensures that the motor reaches and holds the desired position accurately.

- Variable Speed: You can control the speed very precisely, which is essential for dynamic applications.

- Torque Control: Torque can be dynamically controlled, which is advantageous for many industrial uses.

What Is a Brushless Motor?

A brushless motor is an electric motor that operates without mechanical brushes, using electronic commutation instead. These motors use permanent magnets on the rotor and a series of coils on the stator to create motion. Brushless motors are more efficient and longer-lasting compared to their brushed counterparts, as they do not have the wear and tear issues caused by brushes.

Components of a Brushless Motor

- Stator Windings: Fixed coils that create an electromagnetic field.

- Rotor with Permanent Magnets: Moves in response to the magnetic field generated by the stator.

- Electronic Controller: Manages the power supply to the stator coils.

Applications of Brushless Motors

Brushless motors are commonly found in electric vehicles, drone propulsion systems, cooling fans, and appliances due to their high efficiency and low maintenance requirements.

Advantages of Brushless Motors

- High Efficiency: Brushless motors have high power efficiency since there is no energy loss from friction between brushes and the commutator.

- Less Maintenance: The absence of brushes reduces wear and tear, making brushless motors more reliable and requiring less maintenance.

- Higher Speed: Brushless motors can operate at much higher speeds compared to brushed motors.

Comparing Servo Motors and Brushless Motors

| Feature | Servo Motor | Brushless Motor |

|---|---|---|

| Control Type | Closed-loop feedback | Open-loop or sensor-based |

| Precision | Extremely high | Moderate to high |

| Maintenance | Moderate (due to feedback parts) | Low |

| Speed | Moderate | High |

| Torque Control | Dynamic and programmable | Less specific control |

Key Similarities and Differences

Both servo motors and brushless motors share the fundamental design of using permanent magnets and electronic control systems. However, the primary difference lies in how they are controlled and used. Servo motors employ closed-loop control with feedback, allowing them to be highly precise and adaptable. In contrast, brushless motors operate on an open-loop system or sometimes use sensors, providing more generalized power and speed without the pinpoint precision of servos.

Can a Servo Motor Function as a Brushless Motor?

In some scenarios, a servo motor can indeed function similarly to a brushless motor. Here are some considerations:

- Power and Speed Requirements: If your application requires high efficiency and speed without needing ultra-precise positioning, then a servo motor can be run as a brushless motor. By bypassing the closed-loop feedback, you can achieve similar behavior to that of a brushless motor.

- Torque Control: Servo motors excel at controlling torque, making them a suitable replacement in applications where dynamic torque changes are necessary.

- Feedback Limitation: To use a servo motor like a brushless motor, you might need to disable the feedback mechanism, effectively reducing the complexity but also losing the precision advantages. This can be useful for simplified applications where the benefits of the feedback loop are not needed.

Practical Use Cases for Using Servos as Brushless Motors

If you’re considering using a servo motor in place of a brushless motor, it’s essential to evaluate the specific needs of your application.

1. Robotics and Automated Systems

In robotics, servo motors are typically used for their precision. However, in systems where exact positioning is not critical and instead you need general movement with moderate precision, a servo can be treated like a brushless motor.

2. High-Speed Drills and Tools

Brushless motors are often employed in high-speed tools like power drills or rotary tools due to their high efficiency and speed. A servo motor could be used here if there’s a need for both high speed and moderate torque control. For example, by using servo motors in simpler open-loop control, they can serve the same purpose while maintaining the reliability of a brushless system.

Pro Tip: Consider using a servo motor if your project might later require precise feedback. With a simple modification, the motor can be upgraded to a full servo control system for more accuracy.

Considerations for Power Supply and Controllers

If you decide to use servo motors as brushless motors, it’s important to pay attention to the power supply and controllers. Servo drives are designed to receive input from feedback systems to control the motor, while brushless motor controllers use simpler, consistent signals to manage motor speed.

Choosing the Right Power Supply

- Servo Motor Controller: When using a servo as intended, a servo drive is necessary to handle the feedback loop.

- Brushless Motor Controller: To use a servo as a brushless motor, you will need a controller that supports constant current and voltage, ignoring the encoder feedback.

- Power Ratings: Match the motor’s power rating to the controller’s capacity to ensure compatibility. Using mismatched ratings could lead to overheating or inefficient performance.

Advantages of Using Servos in Place of Brushless Motors

| Advantages | Description |

|---|---|

| Flexibility | Can switch between high-precision and general use |

| Customizable Control | Allows switching between torque and speed modes |

| Upgradeability | Easy to implement feedback loops if needed later |

Using servo motors in place of brushless motors can add a lot of flexibility to your system, especially if you’re working on projects that may require modifications in the future.

Drawbacks and Challenges

While using a servo motor like a brushless motor can be advantageous in some situations, there are also challenges:

- Cost: Servo motors tend to be more expensive than brushless motors, primarily because of their integrated sensors and feedback mechanisms.

- Complexity: Adapting the motor to work without feedback can require technical know-how, and removing the feedback may still require disconnecting or disabling hardware components.

- Weight: Servo motors often have additional components like encoders or gears, making them heavier than a comparable brushless motor.

Conclusion

In conclusion, servo motors can be used like brushless motors in many applications, particularly when you require a blend of versatility and general speed control without the intricate feedback mechanisms. However, to do this effectively, the system design must be carefully considered, particularly in regard to the motor controllers and power requirements. Servo motors offer advantages such as dynamic torque control and easy upgrades to precise positioning systems, but they can be more expensive and complex to modify for open-loop control.

If your application needs a reliable motor that can switch between precise and generalized operation, a servo motor may be an excellent choice. Consider the motor’s cost, weight, and control requirements, and consult with experts to determine if adapting a servo to function as a brushless motor aligns with your goals.

To explore more servo motor options, including models that can meet both your precision and speed needs, visit our collection of Panasonic Servo Motors and other related products available at our Servo Motor Store.