How to Check a DC Servo Motor: A Comprehensive Guide

In various industrial applications, DC servo motors play a crucial role in providing precision and control for numerous processes. Whether you are a technician, an engineer, or simply interested in maintaining your equipment, learning how to check a DC servo motor is essential to ensure its optimal performance. This guide will walk you through various techniques to verify if a DC servo motor is functioning correctly. We will cover both basic and advanced methods of testing, providing all the insights needed to evaluate your motor’s condition accurately.

Understanding DC Servo Motors

What is a DC Servo Motor?

A DC servo motor is a type of motor that is designed to provide precise control of angular or linear position, velocity, and acceleration. Unlike regular DC motors, servo motors use feedback mechanisms, usually through an encoder or potentiometer, to adjust their motion and achieve precise outcomes. These motors are used in applications such as robotics, CNC machinery, and automated conveyor systems.

Components of a DC Servo Motor

To understand how to test a DC servo motor, it’s helpful to know its key components:

- Motor Shaft: The part that transmits power from the motor to a connected load.

- Feedback Mechanism: Typically an encoder that gives feedback on the motor’s speed and position.

- Drive Circuit: Powers and controls the motor based on feedback.

- Commutator and Brushes: In brushed DC servos, these components manage current flow.

Servo motors are designed to work in tandem with servo drives, which regulate the power delivered to the motor based on feedback signals, ensuring precise control.

For more information on the various models of DC servo motors, you can visit the Original Panasonic Servo Motor MINAS A5 1KW MDME102GCH/MDME102GCHM page for product specifications.【139†source】

Tools Required for Testing a DC Servo Motor

Before beginning any checks on your DC servo motor, ensure you have the following tools:

- Multimeter: A fundamental tool for measuring resistance, continuity, and voltage.

- Power Supply: Required to power the motor during tests.

- Oscilloscope: Useful for analyzing the encoder’s signals and verifying motor stability.

- Screwdrivers and Wrenches: Necessary to access the motor’s internal components.

These tools will help you conduct thorough tests to determine the condition of the motor and identify any potential issues.

Step-by-Step Guide to Checking a DC Servo Motor

1. Visual Inspection

Begin by conducting a thorough visual inspection of the motor. This step can quickly reveal signs of damage that may affect the motor’s performance.

- Check for Damaged Wires: Look for any visible signs of frayed or burnt wiring. Loose wires are common sources of operational issues.

- Inspect the Motor Housing: Examine the casing for cracks, wear, or signs of overheating.

- Brush Condition (For Brushed Motors): If you are working with a brushed DC motor, inspect the brushes for excessive wear or damage.

2. Testing Resistance with a Multimeter

Motor windings can become damaged due to wear, leading to open circuits or shorts. To identify these issues, you can use a multimeter to check the motor windings.

- Set the Multimeter to Ohms: Measure the resistance between the motor terminals.

- Compare Resistances: Place the probes on different terminals and compare the readings. The values should be consistent across all windings.

- Check for Ground Faults: Place one probe on a motor terminal and the other on the motor casing. If continuity is detected, there is a ground fault that needs repair.

3. Power Testing the Motor

To understand how the motor behaves when powered, apply a steady voltage to see if it rotates smoothly.

- Connect the Motor to the Power Supply: Apply a suitable DC voltage.

- Observe Motor Rotation: Ensure that the shaft rotates without unusual sounds or hesitation. Irregular movement could indicate worn bearings or issues with the commutator.

4. Encoder Testing with an Oscilloscope

An encoder provides feedback on the motor’s position and speed. If the encoder fails, the motor will not respond accurately to commands.

- Connect the Oscilloscope: Attach the probes to the encoder signal wires.

- Analyze the Output Signal: Look for regular, clean pulses. Any irregularities or noise in the waveform could indicate an issue with the encoder or its connections.

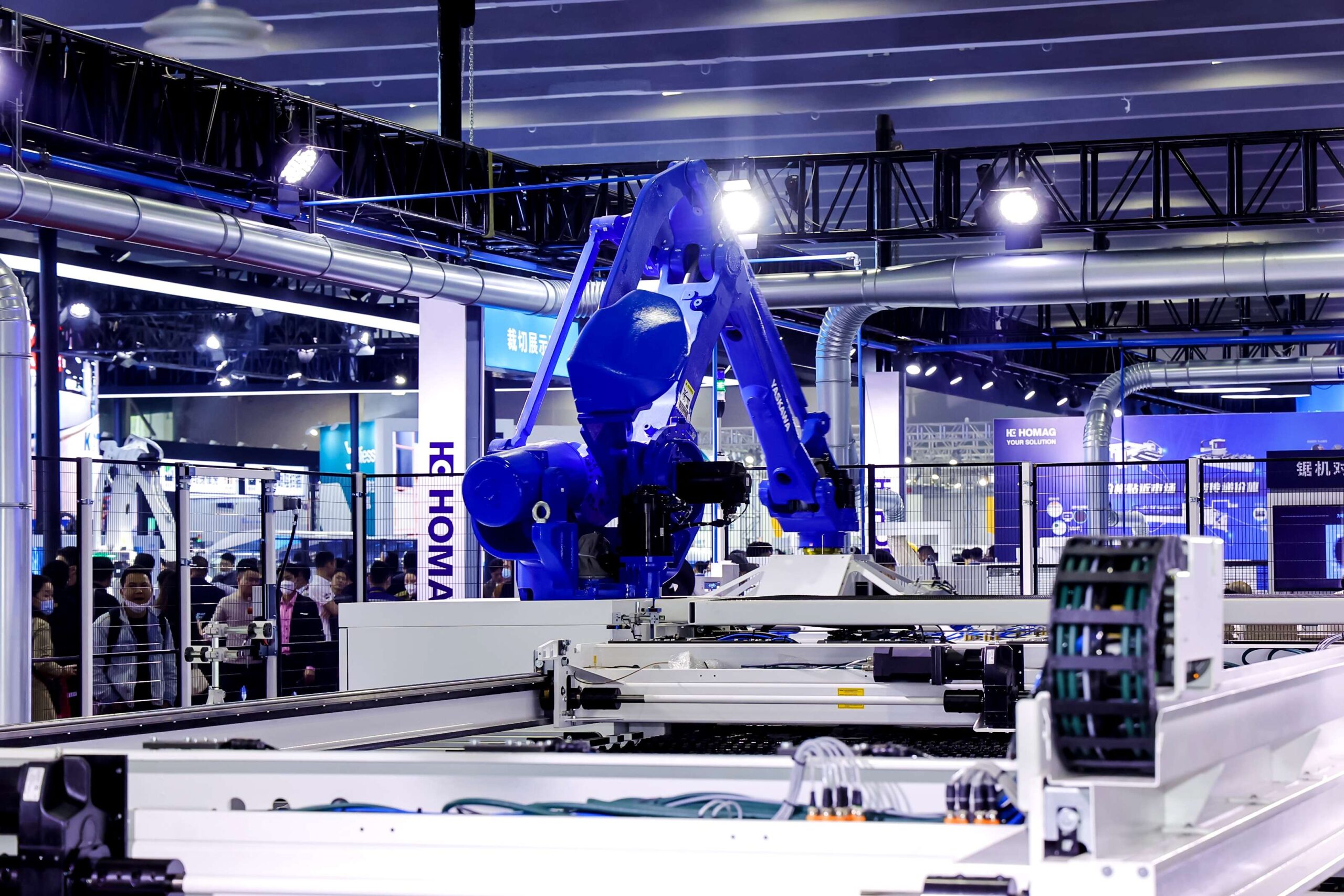

For detailed information on Yaskawa servo drivers, which are often used in tandem with servo motors, check out the Yaskawa SGD7S Servo Drivers.

Common Issues and How to Troubleshoot Them

1. Overheating

Overheating can occur for several reasons:

- High Load: Ensure the motor is not operating above its rated load.

- Poor Ventilation: Make sure the motor is installed in a well-ventilated area.

- Electrical Problems: Incorrect voltage or current may also cause overheating. Check the power supply settings and motor driver configurations.

2. Inconsistent Motor Movement

If the motor’s movement appears inconsistent, there may be an issue with the encoder or with the brushes in brushed motors.

- Check Encoder Signals: Use an oscilloscope to confirm consistent output from the encoder.

- Inspect Brushes: Worn brushes can lead to inconsistent motor movement in brushed DC motors.

3. No Motor Response

If the motor is not responding at all:

- Verify Power Supply: Make sure the motor is receiving the correct power supply voltage.

- Faulty Wiring: Inspect all connections for faults, such as loose wires or incorrect polarity.

- Motor Windings: Test for open circuits in the windings, which could render the motor inoperable.

Preventive Maintenance for DC Servo Motors

Regular Inspections

- Visual Checks: Perform visual inspections regularly to detect signs of wear and tear.

- Electrical Testing: Use a multimeter to measure resistance periodically and confirm that windings are functioning properly.

Lubrication and Cleaning

- Lubricate Bearings: Lubricate the motor’s bearings periodically, especially if the motor runs continuously.

- Brush Replacement: For brushed motors, check the brushes regularly and replace them before they become excessively worn.

Advantages of Proper DC Servo Motor Testing

| Aspect | Benefits of Proper Testing |

|---|---|

| Extended Lifespan | Regular testing ensures early detection of problems, leading to a longer motor lifespan. |

| Cost Savings | Identifying issues early helps avoid expensive repairs or replacements. |

| Efficiency | Properly maintained motors perform more efficiently, reducing power consumption. |

Testing and maintaining your DC servo motor correctly not only extends its operational lifespan but also ensures that your entire system works seamlessly, minimizing downtime and maximizing productivity.

Frequently Asked Questions

1. Can a DC servo motor work without an encoder?

A DC servo motor requires a feedback mechanism, typically an encoder or potentiometer, to function correctly. Without feedback, it cannot achieve precise position control.

2. What is the role of brushes in a DC servo motor?

Brushes in a DC motor provide electrical contact to the commutator, which is essential for maintaining the motor’s movement. Worn brushes can cause inconsistent motor behavior or complete failure.

3. How do I test my servo motor without powering it?

You can test the winding resistance with a multimeter and check the mechanical components visually. These methods give an indication of the motor’s condition without applying power.

4. How often should I perform maintenance on my DC servo motor?

For most applications, it is advisable to perform basic checks every 3-6 months, depending on the motor’s workload. High-duty applications might require more frequent inspections.

Conclusion

Understanding how to check a DC servo motor is an invaluable skill for anyone involved in industrial automation, robotics, or similar fields. By using proper tools like a multimeter or an oscilloscope, and following the correct procedures for testing windings, encoders, and power application, you can ensure the smooth operation of your motor. Moreover, preventive maintenance practices such as regular inspections, brush replacement, and bearing lubrication are crucial for long-term motor health.

For reliable servo motors and accessories, feel free to visit the Servo Motor Store. We provide a wide range of top-quality servo motors that cater to your every need. Proper care and routine diagnostics are key to ensuring that your motors perform efficiently and effectively for years to come.