How to Check a Servo Motor with a Multimeter: A Complete Step-by-Step Guide

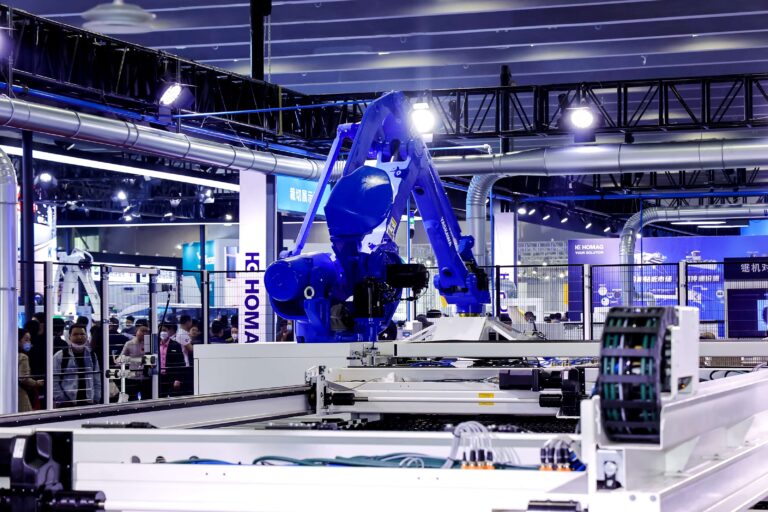

Servo motors are crucial in numerous industries, powering everything from robotics to industrial automation systems. Ensuring that your servo motor works effectively is essential for the reliability of the entire system. In this guide, we’ll explain how to check a servo motor with a multimeter, explore key troubleshooting steps, and help you keep your motor running smoothly. We’ll cover everything in simple terms, ensuring that even beginners can follow along.

Understanding the Basics: What is a Servo Motor?

A servo motor is a specialized rotary actuator that allows precise control of angular or linear position, velocity, and acceleration. It typically operates within a closed-loop control system, using a motor, a sensor for feedback, and a controller to adjust movements precisely. Servo motors are commonly used in robotics, CNC machinery, and industrial automation.

Components of a Servo Motor

- Motor Unit: Converts electrical energy into rotational motion.

- Gearbox: Often used to increase torque while reducing speed.

- Encoder: A feedback mechanism that tells the controller the motor’s position.

- Driver: Powers the motor based on signals received from the controller.

Servo motors are known for their precision and reliability, but it’s essential to keep them in good working condition through proper diagnostics and maintenance.

Looking for a high-quality servo motor for your projects? Check out the Original Panasonic Servo Motor MINAS A5 1KW.

Tools Required to Check a Servo Motor with a Multimeter

Before checking a servo motor, you’ll need the following tools:

- Multimeter: For checking resistance and voltage.

- Screwdrivers: To disassemble the motor if needed.

- Servo Motor Driver: To simulate normal operating conditions during testing.

- Heat Shrink Tubing and Cable Ties: To fix any issues found with the wiring.

These tools will help you effectively diagnose and troubleshoot your servo motor to ensure it functions correctly.

Step-by-Step Guide: How to Check a Servo Motor with a Multimeter

1. Safety First: Disconnect Power

Before handling the servo motor, always disconnect it from the power supply. Electrical currents can pose serious hazards, so it’s essential to prioritize your safety.

- Ensure the Power Supply is Off: Make sure no power is running through the system.

- Discharge Capacitors: In some cases, capacitors may hold residual charges. Discharge them properly to avoid shocks.

2. Visual Inspection of the Motor and Wiring

Before using a multimeter, conduct a visual inspection of the servo motor to identify any obvious problems.

- Check Wires and Connectors: Look for broken wires, loose connections, or frayed cables. Loose or damaged wiring is often a common cause of servo motor failure.

- Inspect the Motor Housing: Check for physical damages, such as cracks or burns, which could indicate overheating or mechanical stress.

3. Testing the Motor Windings with a Multimeter

One of the key tests for a servo motor is checking the motor windings. Here’s how to use a multimeter for this purpose:

- Set the Multimeter to Ohms: Turn your multimeter to the resistance (Ohms) setting.

- Measure Resistance Between Windings: Place the probes on two of the motor terminals and note the reading. Repeat for all combinations of terminals. The readings should be similar; large discrepancies may indicate damage.

- Check for Shorts to Ground: Place one probe on the motor terminal and the other on the motor casing. Any significant reading indicates insulation issues, meaning the winding is shorting to the ground.

Measuring resistance can help determine if any of the windings are damaged or if there’s an electrical short inside the motor.

4. Testing the Feedback Device (Encoder)

Servo motors often rely on encoders for feedback, which helps in accurate positioning.

- Voltage Test: Using the multimeter, set it to voltage mode and measure the voltage output from the encoder wires. The expected voltage should match the manufacturer’s specifications. If the readings are inconsistent, the encoder may be damaged.

- Signal Test: For more detailed diagnostics, an oscilloscope may be required to check the encoder signals, but basic multimeter voltage readings can provide an initial indication of issues.

The SGD7S-120A00A Yaskawa Single Axis Servo Driver can be used to help validate the proper function of servo motors.

5. Test Motor with External Power Supply

To ensure your servo motor is working as expected, you can use an external power supply to energize the motor:

- Connect the Power Supply: Make sure that the voltage matches the rating of the servo motor.

- Observe Motor Response: Once power is supplied, the motor should rotate smoothly without any strange noises or vibrations. Any jerky movements may indicate internal mechanical issues.

6. Evaluate Motor Movement and Noise

- Listen for Unusual Sounds: Motors in good condition should run with minimal noise. Unusual sounds, such as grinding or high-pitched squealing, could indicate bearing wear or misalignment.

- Assess Smoothness of Motion: The motor should rotate smoothly in response to control inputs. Jerky or erratic movement could suggest problems with the encoder, bearings, or misaligned components.

Common Servo Motor Issues and How to Fix Them

1. Motor Not Moving

If the motor does not move:

- Check the Power Supply: Ensure the motor is receiving the proper voltage.

- Inspect Wiring: Loose or broken connections could prevent the motor from functioning.

- Faulty Encoder: If the encoder is faulty, the motor may not receive the correct position signals.

2. Inconsistent Motor Speed

Inconsistent speed is usually a result of:

- Encoder Malfunction: If the encoder cannot provide accurate feedback, the motor speed will fluctuate.

- Worn Bearings: Friction caused by damaged bearings can cause inconsistent speed.

- Driver Issues: Improperly configured or failing drivers may lead to erratic motor behavior.

3. Overheating Motor

Servo motors that overheat could be experiencing:

- Overload Conditions: Make sure the motor is not exceeding its load capacity.

- Insufficient Cooling: Place the motor in a well-ventilated area, ensuring it has sufficient airflow.

- Winding Problems: Damaged windings can lead to inefficient power usage and excessive heat.

Preventative Maintenance for Servo Motors

Maintaining your servo motor is crucial to ensuring a long operational life. Here are some tips:

- Regular Visual Inspections: Look for damaged wires, worn bearings, or overheated components.

- Test Resistance Periodically: Use a multimeter to check resistance across the windings periodically, ensuring no shorts or significant resistance differences arise.

- Lubricate Moving Parts: Lubricate bearings if your motor model requires it to prevent premature wear and tear.

- Environmental Protection: Ensure the motor is protected from dust and moisture using appropriate covers or enclosures.

Frequently Asked Questions

1. How can I use a multimeter to check if a servo motor is working?

To check a servo motor with a multimeter, measure the resistance across motor windings and check for any shorts to the motor casing. Consistent readings indicate a functional motor.

2. What does it mean if my servo motor has erratic movements?

Erratic movement can indicate an issue with the encoder, improper driver settings, or physical obstruction. Conduct a thorough inspection to determine the root cause.

3. Can I repair a damaged servo motor?

Yes, servo motors can often be repaired. Issues like worn bearings or damaged encoders can be fixed. However, major winding issues may require specialized help.

4. What are common signs of a failing servo motor?

Common signs include excessive noise, overheating, erratic movement, and failure to hold position accurately. These indicate problems that should be addressed immediately.

5. Can I use a standard power supply to test a servo motor?

Yes, but ensure the power supply matches the motor’s voltage and current specifications. Mismatched power supplies can damage the motor.

Conclusion

Checking the health of your servo motor using a multimeter is a straightforward but essential process that helps ensure your equipment operates efficiently and reliably. By following the steps outlined above—including visual inspections, multimeter resistance checks, and testing the motor with a power supply—you can identify and address potential problems before they lead to costly downtime. For more advanced diagnostics, a servo driver and oscilloscope may be required, but even basic testing can provide significant insights into your motor’s health.

Proper maintenance, such as regular checks and keeping the motor clean, will also ensure long-lasting performance. If you’re in need of quality servo motors or accessories, visit Servo Motor Store. We provide a wide range of motors, drivers, and accessories designed to meet your needs and keep your projects moving efficiently.

With the right care and diagnostics, you can keep your servo motors working at their best, ensuring accuracy and dependability in your applications.