How to Test a Servo Motor: A Comprehensive Guide

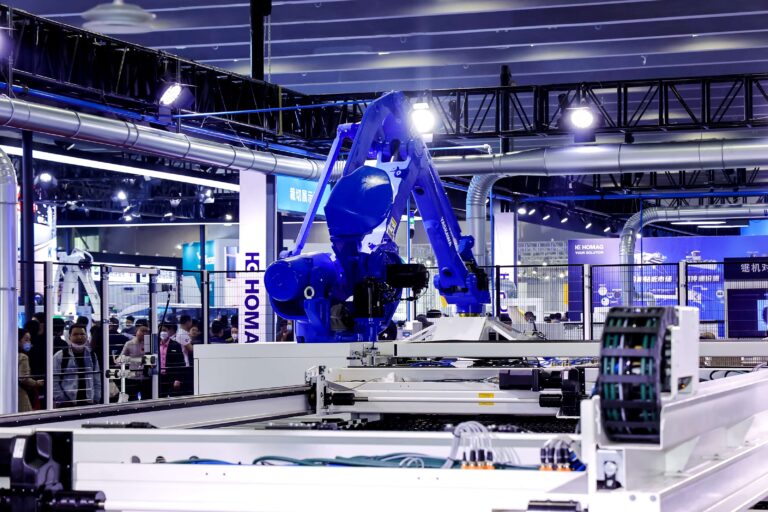

Servo motors are integral to a variety of industrial and consumer applications, ranging from robotics to CNC machinery. Understanding how to test a servo motor is a fundamental skill for anyone working with automation and control systems. This article will provide an in-depth guide on how to test a servo motor, what tools you’ll need, and troubleshooting techniques that can help you identify common issues. We’ll also explore different types of testing methods that ensure your servo motor functions efficiently, reliably, and accurately.

What is a Servo Motor?

A servo motor is a specialized electric motor that is equipped with a feedback mechanism, typically an encoder or potentiometer, to enable precise control of angular or linear position, velocity, and acceleration. Servo motors are widely used in applications where precise positioning is critical, such as in robotics, conveyor belts, and machine tools.

Components of a Servo Motor

To fully understand how to test a servo motor, it’s important to be familiar with its basic components:

- Motor Unit: Converts electrical power into mechanical motion.

- Encoder/Feedback Mechanism: Provides feedback on the motor’s position and speed, enabling accurate control.

- Gearbox: Adjusts torque and speed for specific applications.

- Servo Drive: Controls the flow of power to the motor based on input signals and feedback data.

Servo motors require precise maintenance and testing to ensure each of these components is functioning correctly.

For quality servo motor options, take a look at our Original Panasonic Servo Motors for high precision needs.

Tools Required for Testing a Servo Motor

Before you can start testing a servo motor, make sure you have the following tools available:

- Multimeter: Essential for checking resistance, continuity, and voltage.

- Servo Drive or Power Supply: Used to apply power to the motor during tests.

- Oscilloscope: Helps in analyzing the feedback signals from encoders.

- Screwdrivers and Wrenches: To open motor casings for inspection.

These tools will help you carry out a range of tests, from basic visual checks to more sophisticated electrical diagnostics.

Step-by-Step Guide to Testing a Servo Motor

1. Visual Inspection

The first step in diagnosing any motor issue is a thorough visual inspection. This simple step can often reveal visible signs of damage or issues that can impact the motor’s performance.

- Check Wiring: Look for any frayed, broken, or burnt wiring. Loose connections are a common cause of malfunction.

- Inspect Motor Housing: Look for signs of overheating such as discoloration or cracked parts.

2. Testing Motor Windings with a Multimeter

Motor windings can develop short circuits or open circuits, which can prevent the servo motor from functioning correctly. A multimeter can help test for these issues.

- Set the Multimeter to Ohms: Use the resistance setting to measure the winding resistance.

- Measure Winding Resistance: Place the probes on two terminals of the motor and note the resistance. Repeat for all combinations of terminals. The resistance should be uniform.

- Check for Ground Faults: Place one probe on the terminal and the other on the motor casing. There should be no continuity. If there is, the winding is shorting to the ground.

A significant difference in resistance readings indicates a problem with the windings and the motor may need repair.

3. Testing Encoder Functionality

The encoder is a critical component that provides feedback to the motor controller. An issue with the encoder can lead to inaccurate movement.

- Voltage Test: Use the multimeter to measure the voltage output from the encoder wires. Compare these readings to the manufacturer’s specifications.

- Signal Test with Oscilloscope: If available, use an oscilloscope to inspect the output signals from the encoder. Look for consistent, clean pulses without irregularities.

If the encoder is not functioning correctly, the motor will exhibit erratic movement or may fail to reach target positions.

4. Load Testing the Servo Motor

A load test is useful for understanding how the servo motor behaves under operational conditions.

- Connect to a Servo Drive: Supply power to the motor and gradually increase the load.

- Observe Motor Response: Pay attention to any strange noises, excessive vibration, or hesitation during movement. This may indicate issues such as worn bearings or incorrect drive settings.

A proper load test helps confirm if the motor can handle operational stress without issues such as overheating or mechanical failure.

You can use the Yaskawa Single Axis Servo Driver for precise load testing.

Troubleshooting Common Servo Motor Problems

1. Overheating Motor

Overheating is a common issue with servo motors and can result from several different causes:

- Excessive Load: Operating above the rated load will increase motor temperature.

- Ventilation Issues: Ensure the motor has sufficient airflow to dissipate heat.

- Electrical Issues: Faulty wiring or excessive current can also lead to overheating.

2. Motor Not Moving

If the motor is not moving at all:

- Check Power Supply: Ensure that the motor is getting the appropriate power supply voltage.

- Faulty Encoder: If the encoder is malfunctioning, the motor will not receive accurate positioning information, resulting in no movement.

3. Erratic Movements

Erratic or jittery motor behavior can point to issues such as:

- Incorrect Servo Drive Settings: Verify that your settings, especially the PID control settings, are correctly configured.

- Bearing Wear: Worn bearings can lead to uneven movement and excessive vibrations.

- Feedback Issues: A damaged encoder will lead to poor feedback, causing erratic motor performance.

Regular testing and preventive maintenance can help to catch and fix these issues before they lead to complete motor failure.

Preventive Maintenance for Servo Motors

Preventing servo motor failure starts with regular preventive maintenance.

- Lubricate Moving Parts: If required, keep the motor bearings well-lubricated.

- Test Resistance: Periodically test the winding resistance with a multimeter to check for shorts or inconsistencies.

- Environmental Protection: Protect the motor from moisture and dust by using appropriate enclosures or covers.

Frequently Asked Questions

1. How do I test a servo motor with a multimeter?

To test a servo motor, use a multimeter to measure the resistance across the windings and verify that there are no shorts to the motor body. Consistent readings indicate that the windings are in good condition.

2. Can a faulty servo motor be repaired?

Yes, servo motors can often be repaired, depending on the nature of the fault. Common repairs include replacing the encoder, rewinding the motor, or replacing faulty bearings.

3. Why is my servo motor overheating?

Overheating may occur due to overloading, inadequate ventilation, or electrical issues. It’s important to operate within the recommended specifications to avoid heat buildup.

4. What tools do I need to test a servo motor?

Essential tools include a multimeter, servo drive or power supply, and optionally an oscilloscope for in-depth signal analysis.

5. Can I test a servo motor without powering it?

Yes, basic resistance checks and visual inspections can be done without powering the motor. However, functional tests to observe motor behavior require applying power.

Conclusion

Testing and diagnosing the condition of a servo motor is a vital part of ensuring the reliability of your machinery. By conducting regular visual inspections, resistance checks, and testing the encoder feedback, you can quickly identify and correct problems before they lead to failure. A proactive maintenance plan is key to keeping servo motors running at optimal performance, preventing downtime, and extending the life of your equipment.

If you need high-quality servo motors and accessories, visit Servo Motor Store. We provide a wide range of reliable, precision-driven servo motors designed to meet your needs.

Maintaining your servo motor is not just about performance, but also about ensuring safety, reliability, and longevity. With the right care and regular diagnostics, your servo motors will continue to perform efficiently and effectively in all your applications.